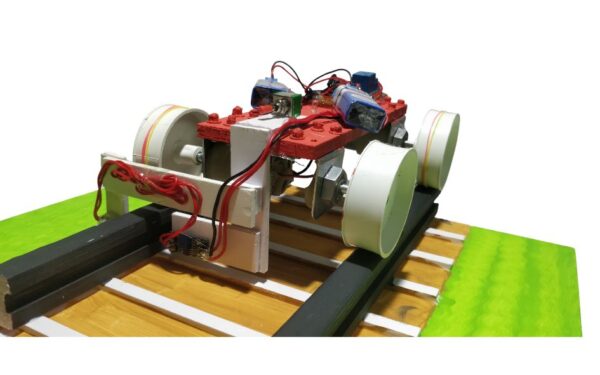

Railway Track Crack Detecting Robot working model

ROBOTIC LAB EQUIPMENT WORKING MODEL / ROBOTIC EXHIBITION WORKING MODEL / ROBOTIC WORKING MODEL

5 in stock

Railway Track Crack Detecting Robot working model

Creating a railway track crack detecting robot working model is an educational and engaging project for students, offering insights into robotics, electronics, mechanical engineering, and railway safety. Here’s a step-by-step guide to building a basic railway track crack detecting robot model:

**Materials Needed:**

1. Chassis (can be made from plastic, wood, or metal)

2. Motors and motor drivers

3. Wheels or tracks for mobility

4. Sensors (such as ultrasonic sensors, infrared sensors, or laser sensors)

5. Microcontroller (Arduino or Raspberry Pi)

6. Battery pack

7. Display module (LCD or OLED)

8. Buzzer or alarm module

9. Enclosure for housing electronics

10. Glue, tape, screws, and basic tools

**Steps:**

**1. Design the Chassis:**

– Sketch out the design for the robot’s chassis, considering factors like stability, weight distribution, and space for components.

– Choose materials for the chassis that are sturdy and lightweight, suitable for carrying the robot’s components.

**2. Install the Motors and Mobility System:**

– Attach motors to the chassis and mount wheels or tracks for mobility.

– Connect the motors to motor drivers and wire them to the microcontroller for control.

**3. Integrate Crack Detection Sensors:**

– Install crack detection sensors onto the chassis, ensuring they are positioned to scan the railway track for cracks.

– Choose sensors such as ultrasonic sensors, infrared sensors, or laser sensors that are suitable for detecting cracks on the track surface.

– Wire the sensors to the microcontroller for data acquisition and processing.

**4. Design the Display and Alarm System:**

– Connect a display module (LCD or OLED) to the microcontroller to show real-time crack detection data.

– Install a buzzer or alarm module to provide audible alerts when cracks are detected on the track.

**5. Wire and Connect Electronics:**

– Connect all electronic components, including motors, sensors, display module, and alarm module, to the microcontroller.

– Use jumper wires and connectors to make secure connections and avoid loose connections.

**6. Program the Microcontroller:**

– Write code to read data from the crack detection sensors, process the information, and display crack detection results on the display module.

– Implement algorithms to trigger the alarm module when cracks are detected on the track.

– Use Arduino IDE or Python for Raspberry Pi to program the microcontroller.

**7. Test and Calibration:**

– Test the robot on a mock-up railway track with simulated cracks to verify the accuracy of crack detection.

– Calibrate the sensors and adjust detection thresholds as needed to ensure reliable crack detection.

**8. Demonstration and Presentation:**

– Showcase the railway track crack detecting robot to students, teachers, or parents, demonstrating its functionality and effectiveness.

– Explain the importance of detecting track defects for railway safety and the role of robots in railway maintenance and inspection.

– Discuss potential applications of the robot in real-world scenarios, such as automated track inspection in railway operations.

Building a railway track crack detecting robot working model provides students with hands-on experience in robotics, electronics, programming, and railway safety, fostering critical thinking, problem-solving skills, and STEM literacy. It offers an engaging educational opportunity to learn about railway infrastructure and the use of technology for railway maintenance and safety.

Enhanced Track Safety

Precision Monitoring for Railway Integrity Secure your railway operations with the Railway Track Crack Detecting Robot Working Model. This sophisticated robot is engineered to patrol railway tracks and detect any signs of damage or cracks using advanced sensing technology. By providing real-time alerts and precise location data, it helps prevent accidents and maintains the safety of rail networks.

State-of-the-Art Detection Technology

Advanced Sensing for Flawless Tracks The Railway Track Crack Detecting Robot is equipped with ultrasonic and electromagnetic sensors designed to identify minute imperfections along the tracks that are invisible to the human eye. This allows for immediate maintenance actions to be taken before minor issues escalate into major problems, ensuring continuous safe operation of rail services.

Why Choose Our Track Inspection Robot?

Reliability and Proactive Maintenance Investing in the Railway Track Crack Detecting Robot means prioritizing the safety and reliability of your railway services. This robot reduces the need for manual inspections, cutting down on labor costs and minimizing human error. Its continuous monitoring capability allows for proactive maintenance, significantly enhancing track safety and service reliability.

| Weight | 1.5 kg |

|---|---|

| Dimensions | 50 × 40 × 40 cm |

You must be logged in to post a review.

Reviews

There are no reviews yet