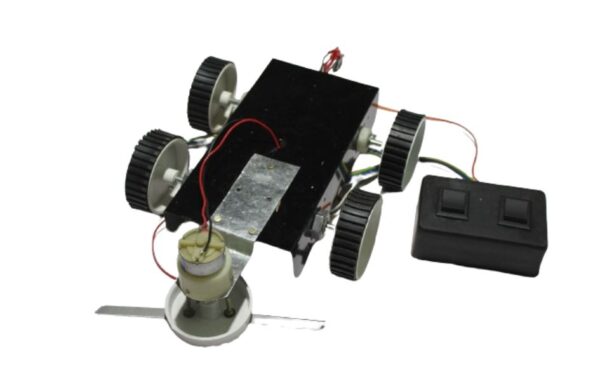

Grass Cutting Robot working model

ROBOTIC LAB EQUIPMENT WORKING MODEL / ROBOTIC EXHIBITION WORKING MODEL / ROBOTIC WORKING MODEL

5 in stock

Refund

Unfortunately, once an order is placed, there is no refund available. However, we do offer exchanges for defective or damaged items.

Due to the nature of our products and the potential for misuse or mishandling, we do not offer refunds. We believe in customer satisfaction and strive to provide quality exchanges for any issues that may arise.

If you have received a defective or damaged item, please contact our customer service team and they will assist you with the exchange process. Please note that exchanges are subject to availability and product conditions.

We do not offer refunds for change of mind purchases, but we do offer exchanges for valid reasons such as defects or damages.

Delivery

My Science Kart delivers orders through a reliable and efficient shipping service to ensure your products arrive safely and on time.

Yes, you can easily track your order from My Science Kart by using the tracking number provided to you once your order has been shipped.

If you have any issues with your order from My Science Kart, please contact our customer service team who will be happy to assist you and resolve any problems.

Payment

You can pay for your purchases on My Science Kart using various payment methods such as credit/debit cards, net banking, UPI’s and mobile wallets.

Yes, we use industry-standard encryption technology to protect your payment information and ensure that it is secure.

If you have any payment-related queries or issues on My Science Kart, you can contact our customer support team through the website or email us at support@mysciencekart.com.

Grass Cutting Robot working model

Creating a simple grass-cutting robot for students can be a fun and educational project that involves elements of mechanical engineering, electronics, and programming. Here’s a basic outline of how such a project could work:

**1. Mechanical Design:**

– Start by designing a chassis for the robot using materials like wood, plastic, or metal. The chassis should be sturdy and able to support the weight of the robot components.

– Attach wheels or tracks to the chassis for movement. Depending on the complexity of the design, you can use motors to drive the wheels.

– Design a cutting mechanism, such as a rotating blade or string trimmer, that can be attached to the robot for cutting grass.

**2. Electronics:**

– Select motors and motor controllers suitable for driving the wheels and cutting mechanism. Make sure they are compatible with the power source you plan to use.

– Include sensors such as bump sensors or ultrasonic sensors to detect obstacles and avoid collisions.

– Choose a microcontroller board, such as Arduino or Raspberry Pi, to control the robot’s movements and functions.

**3. Programming:**

– Write code to control the motors for forward, backward, and turning movements. Implement algorithms for obstacle avoidance using sensor data.

– Develop routines for activating the cutting mechanism when the robot detects grass.

– Incorporate logic for safety features, such as automatically stopping the cutting mechanism when the robot is lifted or tilted.

**4. Testing and Iteration:**

– Assemble the robot according to your design and test each component individually.

– Conduct field tests to assess the robot’s performance in cutting grass and navigating the environment.

– Iterate on your design and programming based on test results, making adjustments as needed to improve functionality and efficiency.

**5. Documentation and Presentation:**

– Document your project with clear instructions, diagrams, and code explanations. Include a bill of materials detailing all components used.

– Prepare a presentation to showcase your grass-cutting robot to classmates, teachers, or parents. Demonstrate how it works and explain the design and engineering principles behind it.

**6. Safety Considerations:**

– Ensure that safety precautions are taken during the construction and operation of the robot, especially when working with sharp objects or moving parts.

– Supervise students closely, particularly during testing and demonstration phases, to prevent accidents or injuries.

By following these steps, students can gain hands-on experience in robotics, engineering, and programming while building a functional grass-cutting robot. This project encourages creativity, problem-solving skills, and teamwork, making it an engaging educational activity for students of various ages.

Effortless Lawn Maintenance

Automate Your Lawn Care with Advanced Robotics Introduce the Grass Cutting Robot Working Model to your home or business for an impeccably maintained lawn without the effort. This robot is engineered to navigate through your yard independently, using sophisticated sensors to avoid obstacles and efficiently cut grass. Perfect for anyone seeking a pristine lawn with minimal input, this robotic mower provides consistent, high-quality results.

Smart Features for a Perfect Cut

Precision and Intelligence Combined The Grass Cutting Robot is equipped with GPS tracking and programmable patterns to ensure every inch of your lawn is covered. It adjusts its cutting height automatically based on the grass length, promoting healthy lawn growth and uniform aesthetics. With its quiet operation and eco-friendly design, it’s the smart choice for modern lawn care.

Why Choose Our Robotic Lawn Mower?

Convenience and Quality in Lawn Management Opting for our Grass Cutting Robot means prioritizing both convenience and quality. This model allows you to schedule mowing times that fit your lifestyle, and its electric operation reduces carbon emissions. Durable and reliable, it’s designed to handle various lawn types and sizes, making it an essential tool for anyone serious about lawn care.

| Weight | 1.5 kg |

|---|---|

| Dimensions | 40 × 20 × 20 cm |

You must be logged in to post a review.

Q & A

Related Products

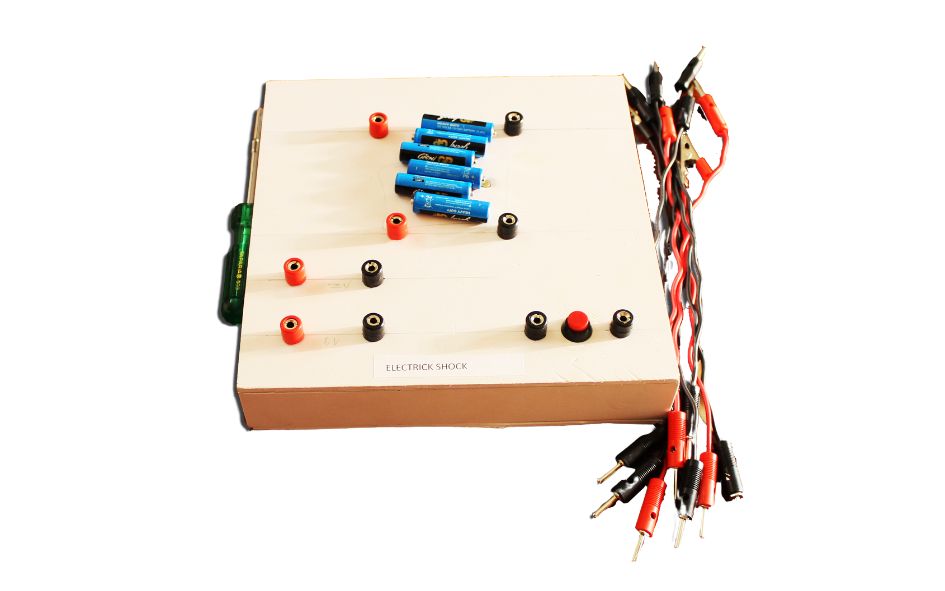

KIRCHHOFF'S LOOP LAW WORKING MODEL

- ✓ 100% Quality products

HEAT, TEMPERATURE and KINETIC ENERGY WORKING MODEL

- ✓ 100% Quality products

REFLECTION OF LIGHT PLANE MIRRORS/LAWS OF REFLECTION WORKING MODEL

- ✓ 100% Quality products

OERSTED EXPERIMENT WORKING MODEL

- ✓ 100% Quality products

MULTIMETER

- ✓ 100% Quality products

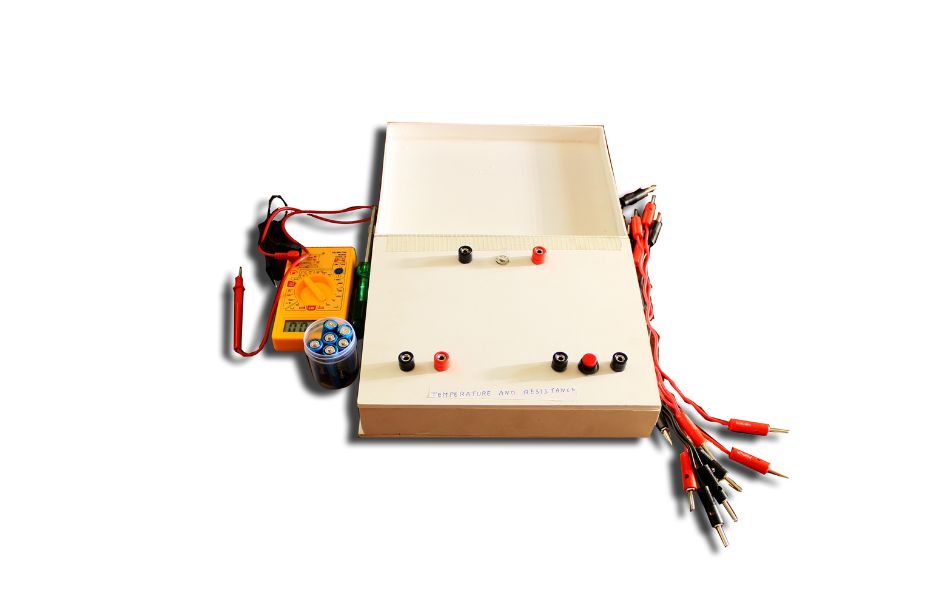

TEMPERATURE AND RESISTANCE WORKING MODEL

- ✓ 100% Quality products

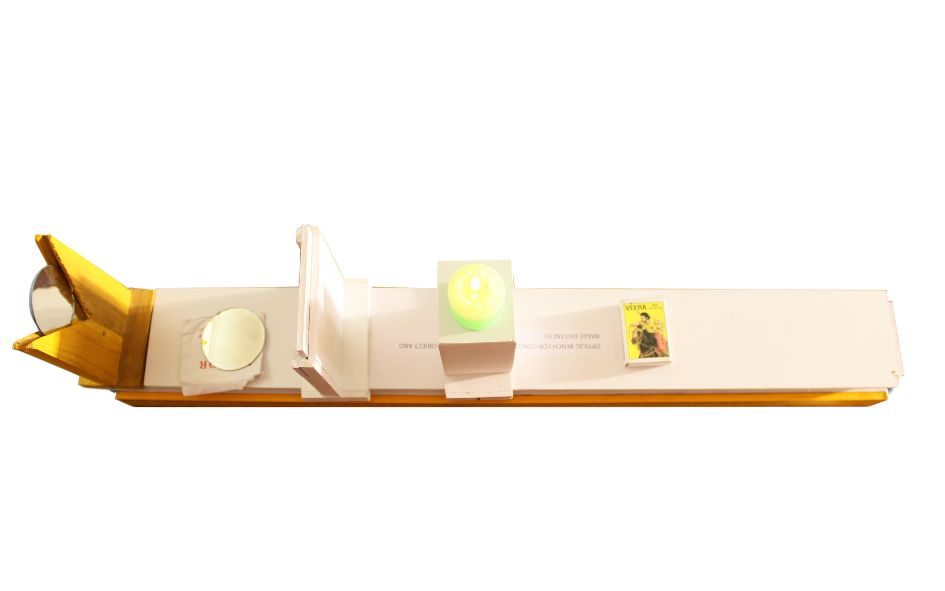

OPTICAL BENCH FOR CONVEX LENS FOR MEASURING OBJECT AND IMAGE DISTANCE WORKING MODEL

- ✓ 100% Quality products

RIGHT HAND RULE - 1 WORKING MODEL

- ✓ 100% Quality products

Product categories

- Circuits & Projects 233

- My Science Kart 665

- Raw Materials For Projects & Lab Equipments 381

- Science Exhibition 516

- Science Exhibition Projects & Working Models 344

- Biology Science Exhibition Projects & Working Models 31

- Chemistry Science Exhibition Projects & Working Models 12

- Mathematics Science Exhibition projects & Working Models 7

- Physics Science Exhibition Projects & Working Models 129

- Robotics Science Exhibition Projects & Working Models 23

- Social Science Exhibition Projects & Working Models 20

- Science Lab Equipments With Working Models 363

Cart

TRULY INDIAN EDUCATION BRAND

Over 10,000+ Happy Customers

My Science Kart

Address:- Ground floor, Lakshmi Nagar, D.No:- 40-1/1-5, PVP Mall Backside, Mogalrajapuram, Labbipet, Vijayawada, Andhra Pradesh 520010

7673977997, 0866-3543677

mysciencekart@gmail.com

Categories

MAP

© My Science Kart 2024, Designed & Developed By Synfocy Tech Solutions

Reviews

There are no reviews yet